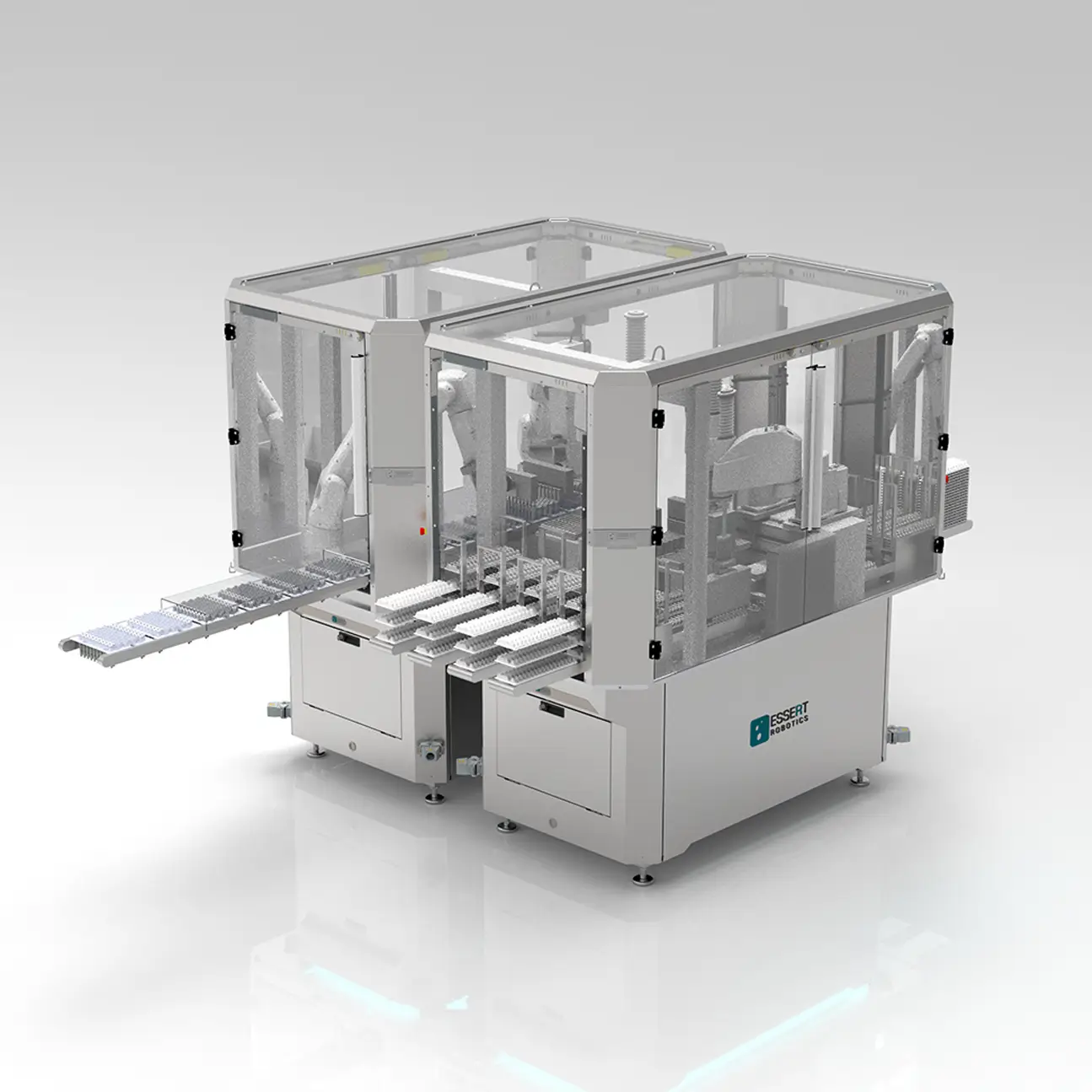

Tub to Rondo Tray and Back

Fully automate the bidirectional transfer of syringes between tubs and Rondo trays with a robotic system designed for maximum flexibility and throughput.

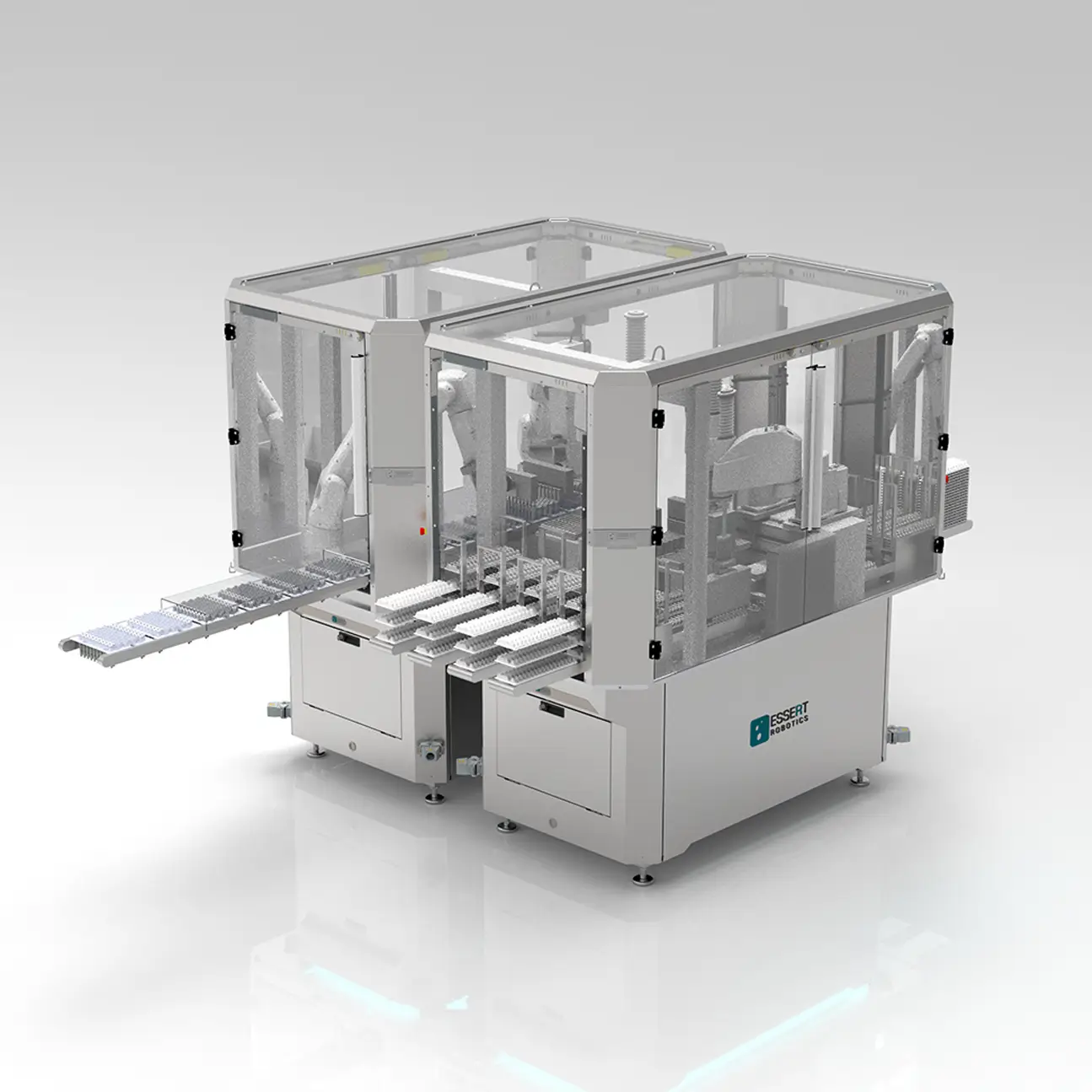

Tub to Rondo Tray and Back

Fully automate the bidirectional transfer of syringes between tubs and Rondo trays with a robotic system designed for maximum flexibility and throughput.

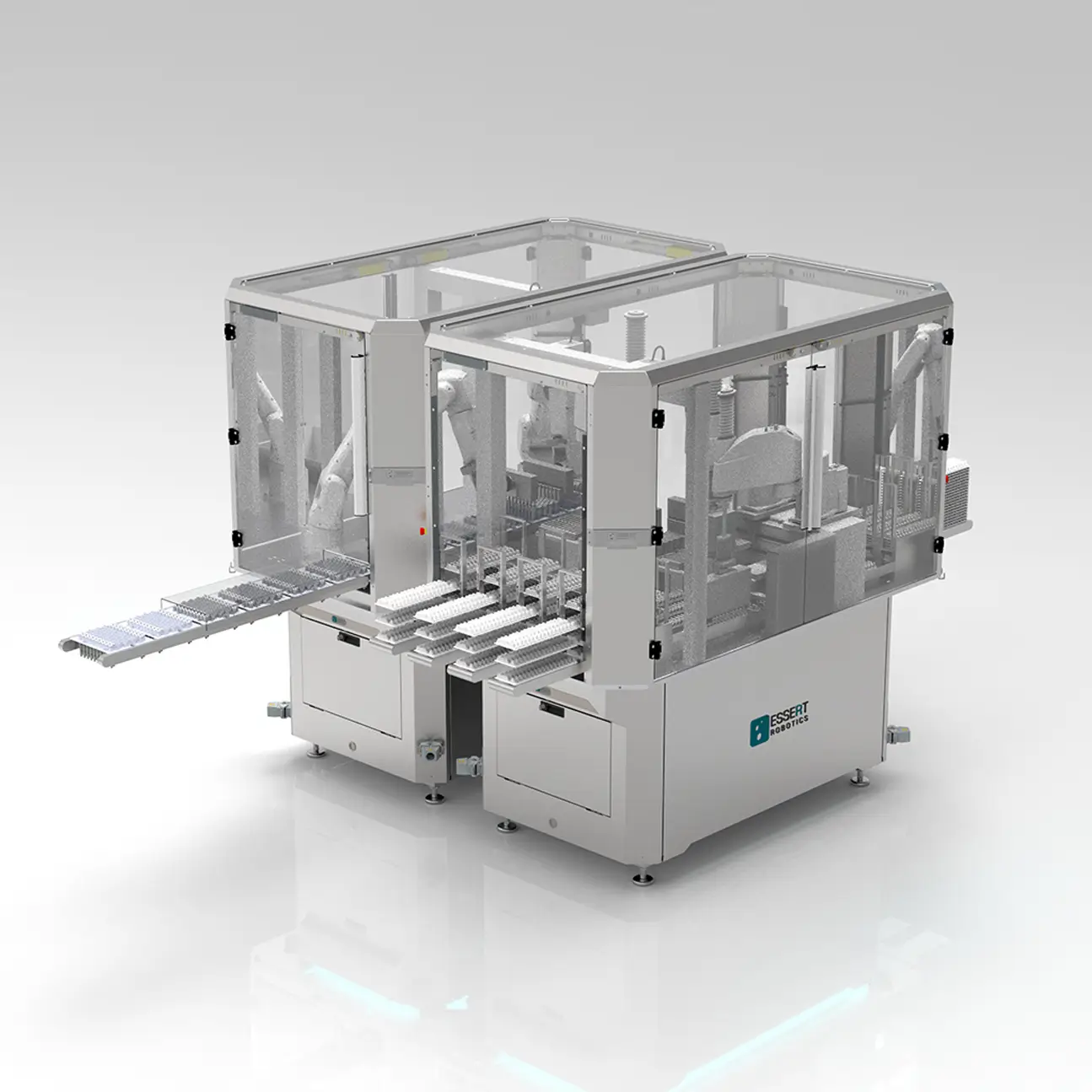

Tub to Rondo Tray and Back

Fully automate the bidirectional transfer of syringes between tubs and Rondo trays with a robotic system designed for maximum flexibility and throughput.

Is Manual Syringe Handling Creating a Bottleneck in Your Process?

Your production requires the frequent transfer of syringes between tubs and Rondo trays, a process that is likely performed manually. This repetitive task is not only slow and costly but also introduces the risk of human error and contamination. It’s a critical process step that is holding back your facility’s true potential for efficiency and throughput.

200 PPM Throughput

Achieve a high-speed cycle rate of 200 parts per minute, dramatically increasing your production capacity and overall equipment effectiveness (OEE).

Bidirectional Flexibility

The system is engineered for full bidirectional processing, allowing you to transfer syringes from Tub to Rondo Tray and from Rondo Tray back to Tub.

Quick Format Changes

Thanks to our software-based approach and minimal setup effort, format changes for different tray sizes can be executed quickly and easily.

Proven Reliability

Built on our MicroFactory Ecosystem, the system uses standardized handling modules that are already operating successfully at multiple customer sites.

Fully Collaborative

Advanced collaborative and SCARA robots work safely alongside your employees, eliminating the need for bulky safety fences and improving accessibility.

Seamless Integration

The modular system can be integrated as a standalone solution or connected with optional automated de-palletizing and outfeed modules.

Is Manual Syringe Handling Creating a Bottleneck in Your Process?

Your production requires the frequent transfer of syringes between tubs and Rondo trays, a process that is likely performed manually. This repetitive task is not only slow and costly but also introduces the risk of human error and contamination. It’s a critical process step that is holding back your facility’s true potential for efficiency and throughput.

200 PPM Throughput

Achieve a high-speed cycle rate of 200 parts per minute, dramatically increasing your production capacity and overall equipment effectiveness (OEE).

Bidirectional Flexibility

The system is engineered for full bidirectional processing, allowing you to transfer syringes from Tub to Rondo Tray and from Rondo Tray back to Tub.

Quick Format Changes

Thanks to our software-based approach and minimal setup effort, format changes for different tray sizes can be executed quickly and easily.

Proven Reliability

Built on our MicroFactory Ecosystem, the system uses standardized handling modules that are already operating successfully at multiple customer sites.

Fully Collaborative

Advanced collaborative and SCARA robots work safely alongside your employees, eliminating the need for bulky safety fences and improving accessibility.

Seamless Integration

The modular system can be integrated as a standalone solution or connected with optional automated de-palletizing and outfeed modules.

Is Manual Syringe Handling Creating a Bottleneck in Your Process?

Your production requires the frequent transfer of syringes between tubs and Rondo trays, a process that is likely performed manually. This repetitive task is not only slow and costly but also introduces the risk of human error and contamination. It’s a critical process step that is holding back your facility’s true potential for efficiency and throughput.

200 PPM Throughput

Achieve a high-speed cycle rate of 200 parts per minute, dramatically increasing your production capacity and overall equipment effectiveness (OEE).

Bidirectional Flexibility

The system is engineered for full bidirectional processing, allowing you to transfer syringes from Tub to Rondo Tray and from Rondo Tray back to Tub.

Quick Format Changes

Thanks to our software-based approach and minimal setup effort, format changes for different tray sizes can be executed quickly and easily.

Proven Reliability

Built on our MicroFactory Ecosystem, the system uses standardized handling modules that are already operating successfully at multiple customer sites.

Fully Collaborative

Advanced collaborative and SCARA robots work safely alongside your employees, eliminating the need for bulky safety fences and improving accessibility.

Seamless Integration

The modular system can be integrated as a standalone solution or connected with optional automated de-palletizing and outfeed modules.

World-class CDMOs like VETTER Pharma rely on our solutions.

"ESSERT's automation platform impresses with its flexibility and modularity as well as the integration of state-of-the-art technologies.”

Arno Schroff

Department manager for plant and site development.

World-class CDMOs like VETTER Pharma rely on our solutions.

"ESSERT's automation platform impresses with its flexibility and modularity as well as the integration of state-of-the-art technologies.”

Arno Schroff

Department manager for plant

and site development.

World-class CDMOs like VETTER Pharma rely on our solutions.

"ESSERT's automation platform impresses with its flexibility and modularity as well as the integration of state-of-the-art technologies.”

Arno Schroff

Department manager for plant and site development.

Tub | Rondo Tray Retrayer

Our Retraying Automation seamlessly transfers syringes between tubs and Rondo trays in both directions at up to 200 parts per minute, ensuring process reliability and maximizing throughput.

Multi-Format Gripper

A specialized gripper places syringes individually, allowing it to handle various tray sizes (7, 10, 14, 16, 20) and compensate for missing products.

Pitch Adjustment

The syringe gripper features an integrated cylinder mechanism that automatically converts the tub pitch to the required Rondo tray pitch.

Camera Verification

Integrated camera systems are used throughout the process to verify syringe quantity and ensure correct loading, guaranteeing process quality.

Large Tray Buffer

The Rondo Tray Module includes a large buffer for up to 80 trays (4 stacks of 20), enabling long periods of autonomous operation.

Smart Distribution

A smart carrier system ensures syringes are distributed evenly between the two SCARA robots for maximum speed and efficiency.

Quick Deployment

The completely modular design allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT), reducing project timelines.

Tub | Rondo Tray Retrayer

Our Retraying Automation seamlessly transfers syringes between tubs and Rondo trays in both directions at up to 200 parts per minute, ensuring process reliability and maximizing throughput.

Multi-Format Gripper

A specialized gripper places syringes individually, allowing it to handle various tray sizes (7, 10, 14, 16, 20) and compensate for missing products.

Pitch Adjustment

The syringe gripper features an integrated cylinder mechanism that automatically converts the tub pitch to the required Rondo tray pitch.

Camera Verification

Integrated camera systems are used throughout the process to verify syringe quantity and ensure correct loading, guaranteeing process quality.

Large Tray Buffer

The Rondo Tray Module includes a large buffer for up to 80 trays (4 stacks of 20), enabling long periods of autonomous operation.

Smart Distribution

A smart carrier system ensures syringes are distributed evenly between the two SCARA robots for maximum speed and efficiency.

Quick Deployment

The completely modular design allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT), reducing project timelines.

Tub | Rondo Tray Retrayer

Our Retraying Automation seamlessly transfers syringes between tubs and Rondo trays in both directions at up to 200 parts per minute, ensuring process reliability and maximizing throughput.

Multi-Format Gripper

A specialized gripper places syringes individually, allowing it to handle various tray sizes (7, 10, 14, 16, 20) and compensate for missing products.

Pitch Adjustment

The syringe gripper features an integrated cylinder mechanism that automatically converts the tub pitch to the required Rondo tray pitch.

Camera Verification

Integrated camera systems are used throughout the process to verify syringe quantity and ensure correct loading, guaranteeing process quality.

Large Tray Buffer

The Rondo Tray Module includes a large buffer for up to 80 trays (4 stacks of 20), enabling long periods of autonomous operation.

Smart Distribution

A smart carrier system ensures syringes are distributed evenly between the two SCARA robots for maximum speed and efficiency.

Quick Deployment

The completely modular design allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT), reducing project timelines.

System Extensions

Scale Your Automation with Optional Modules

Enhance your Retraying Automation with these fully integrated modules for a completely hands-off process.

System Extensions

Scale Your Automation with Optional Modules

Enhance your Retraying Automation with these fully integrated modules for a completely hands-off process.

System Extensions

Scale Your Automation with Optional Modules

Enhance your Retraying Automation with these fully integrated modules for a completely hands-off process.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.