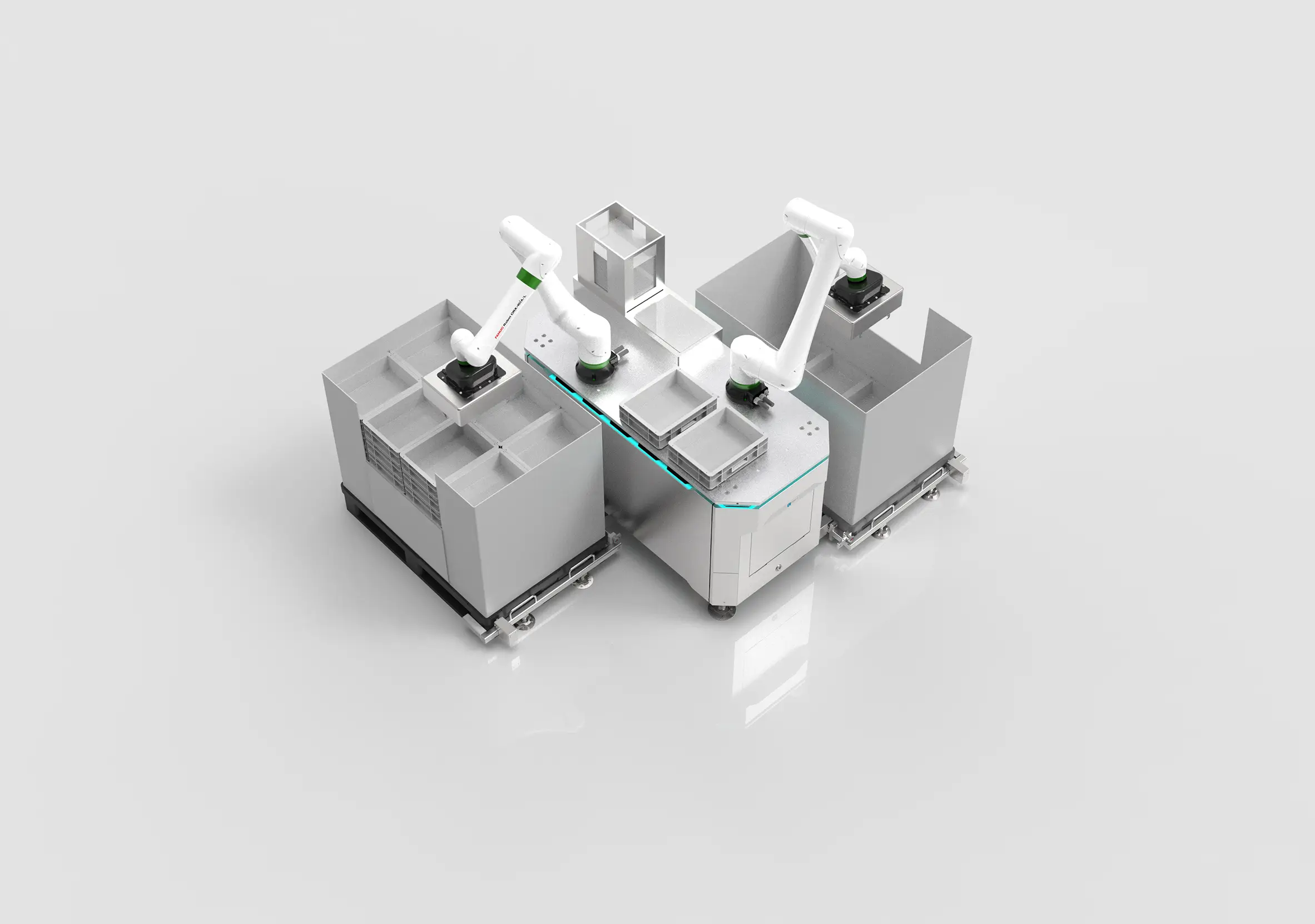

Vial Handling with RoboVial

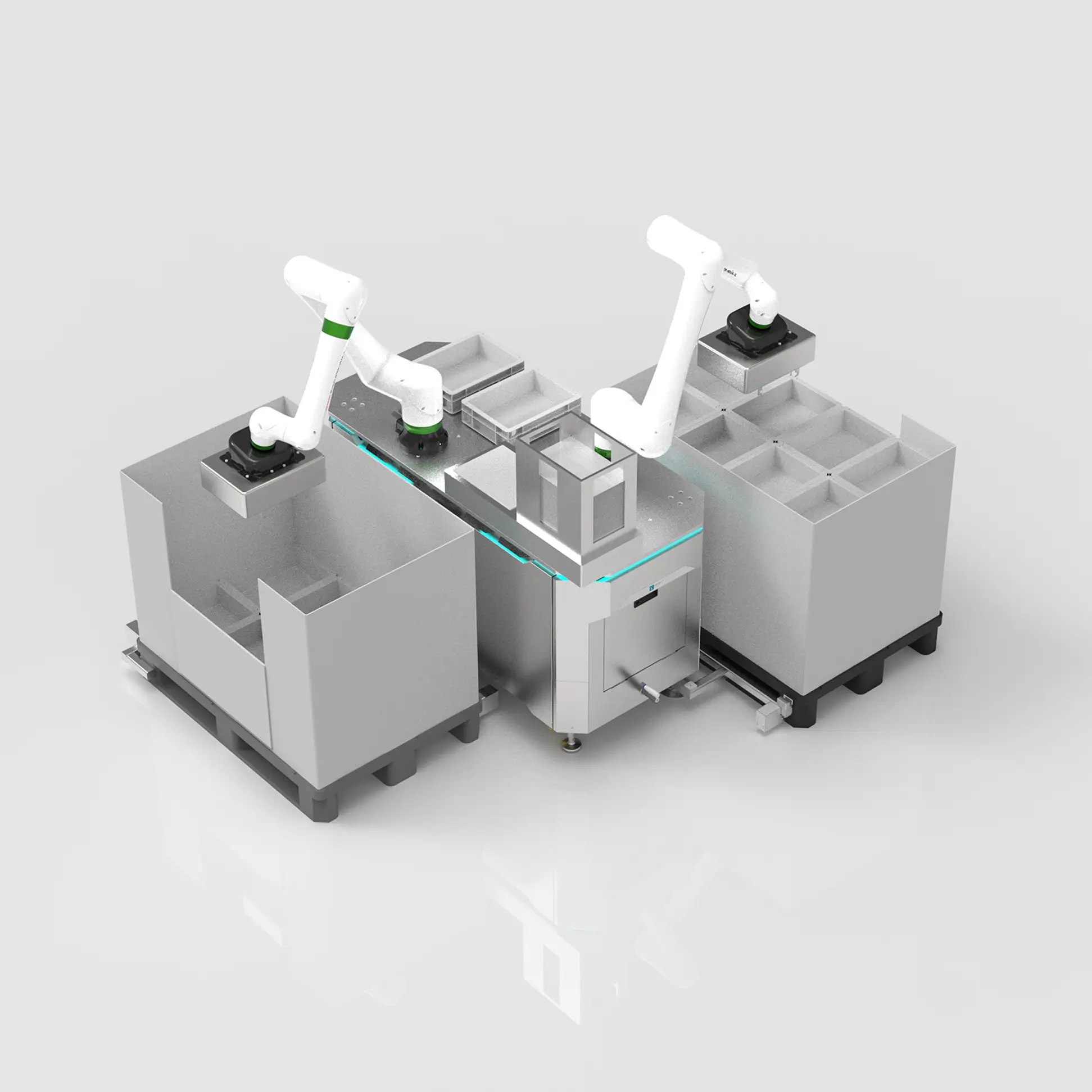

Streamline your end-of-line process with a fully collaborative robot workstation that unloads filling lines, tends inspection machines, and precisely packs vials into multi-use boxes.

Vial Handling with RoboVial

Streamline your end-of-line process with a fully collaborative robot workstation that unloads filling lines, tends inspection machines, and precisely packs vials into multi-use boxes.

Vial Handling with RoboVial

Streamline your end-of-line process with a fully collaborative robot workstation that unloads filling lines, tends inspection machines, and precisely packs vials into multi-use boxes.

Is Manual Handling Undermining Your Line Performance?

Your filling and inspection machines are running at peak performance, but the process of manually unloading and packing creates a significant bottleneck. This repetitive, physically demanding task not only slows down your entire production line but also increases the risk of musculoskeletal disorders (MSDs) for your skilled workforce. It’s time to automate this critical final step.

Protect Your Team

Eliminate repetitive manual lifting and reduce the risk of costly MSD injuries. Show a clear commitment to employee well-being, improving morale and retention.

Maximize Throughput

The RoboVial ensures continuous operation, eliminating manual bottlenecks between your filling or inspection lines and final production steps.

Seamless Integration

Our solution requires no complex interfaces with your existing filling or inspection machines. The smart design ensures a simple, fast, and cost-effective integration.

Proven Reliability

The system is built on our proven, standardized RoboTub handling modules that are already successfully operating at multiple customer sites.

Fully Collaborative

Certified collaborative robots work safely alongside your employees without the need for bulky safety fences, enabling flexible human-machine interaction.

Minimal Footprint

The compact, modular design saves valuable production floor space and reduces operational costs, making it an efficient addition to any facility.

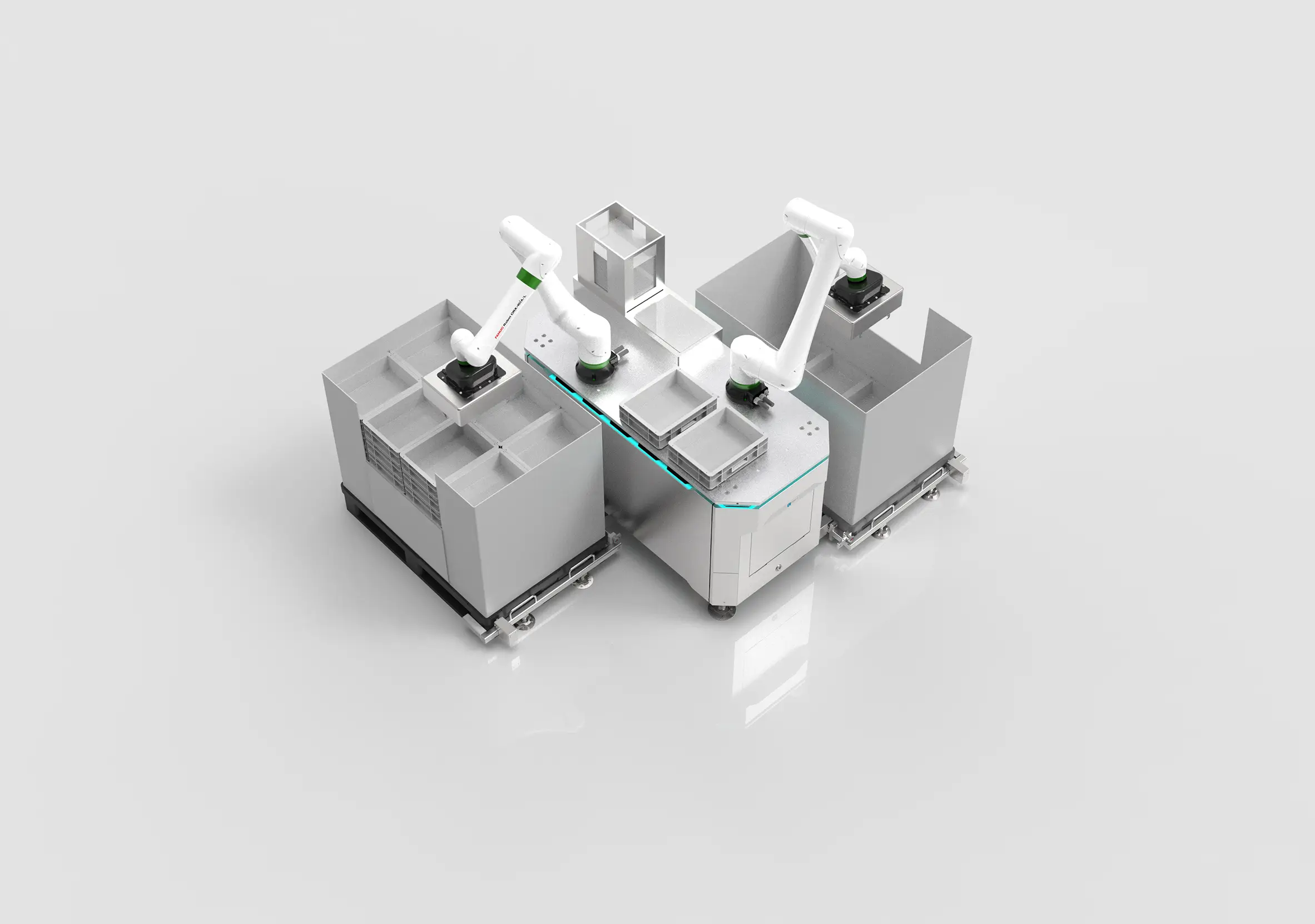

Is Manual Handling Undermining Your Line Performance?

Your filling and inspection machines are running at peak performance, but the process of manually unloading and packing creates a significant bottleneck. This repetitive, physically demanding task not only slows down your entire production line but also increases the risk of musculoskeletal disorders (MSDs) for your skilled workforce. It’s time to automate this critical final step.

Protect Your Team

Eliminate repetitive manual lifting and reduce the risk of costly MSD injuries. Show a clear commitment to employee well-being, improving morale and retention.

Maximize Throughput

The RoboVial ensures continuous operation, eliminating manual bottlenecks between your filling or inspection lines and final production steps.

Seamless Integration

Our solution requires no complex interfaces with your existing filling or inspection machines. The smart design ensures a simple, fast, and cost-effective integration.

Proven Reliability

The system is built on our proven, standardized RoboTub handling modules that are already successfully operating at multiple customer sites.

Fully Collaborative

Certified collaborative robots work safely alongside your employees without the need for bulky safety fences, enabling flexible human-machine interaction.

Minimal Footprint

The compact, modular design saves valuable production floor space and reduces operational costs, making it an efficient addition to any facility.

Is Manual Handling Undermining Your Line Performance?

Your filling and inspection machines are running at peak performance, but the process of manually unloading and packing creates a significant bottleneck. This repetitive, physically demanding task not only slows down your entire production line but also increases the risk of musculoskeletal disorders (MSDs) for your skilled workforce. It’s time to automate this critical final step.

Protect Your Team

Eliminate repetitive manual lifting and reduce the risk of costly MSD injuries. Show a clear commitment to employee well-being, improving morale and retention.

Maximize Throughput

The RoboVial ensures continuous operation, eliminating manual bottlenecks between your filling or inspection lines and final production steps.

Seamless Integration

Our solution requires no complex interfaces with your existing filling or inspection machines. The smart design ensures a simple, fast, and cost-effective integration.

Proven Reliability

The system is built on our proven, standardized RoboTub handling modules that are already successfully operating at multiple customer sites.

Fully Collaborative

Certified collaborative robots work safely alongside your employees without the need for bulky safety fences, enabling flexible human-machine interaction.

Minimal Footprint

The compact, modular design saves valuable production floor space and reduces operational costs, making it an efficient addition to any facility.

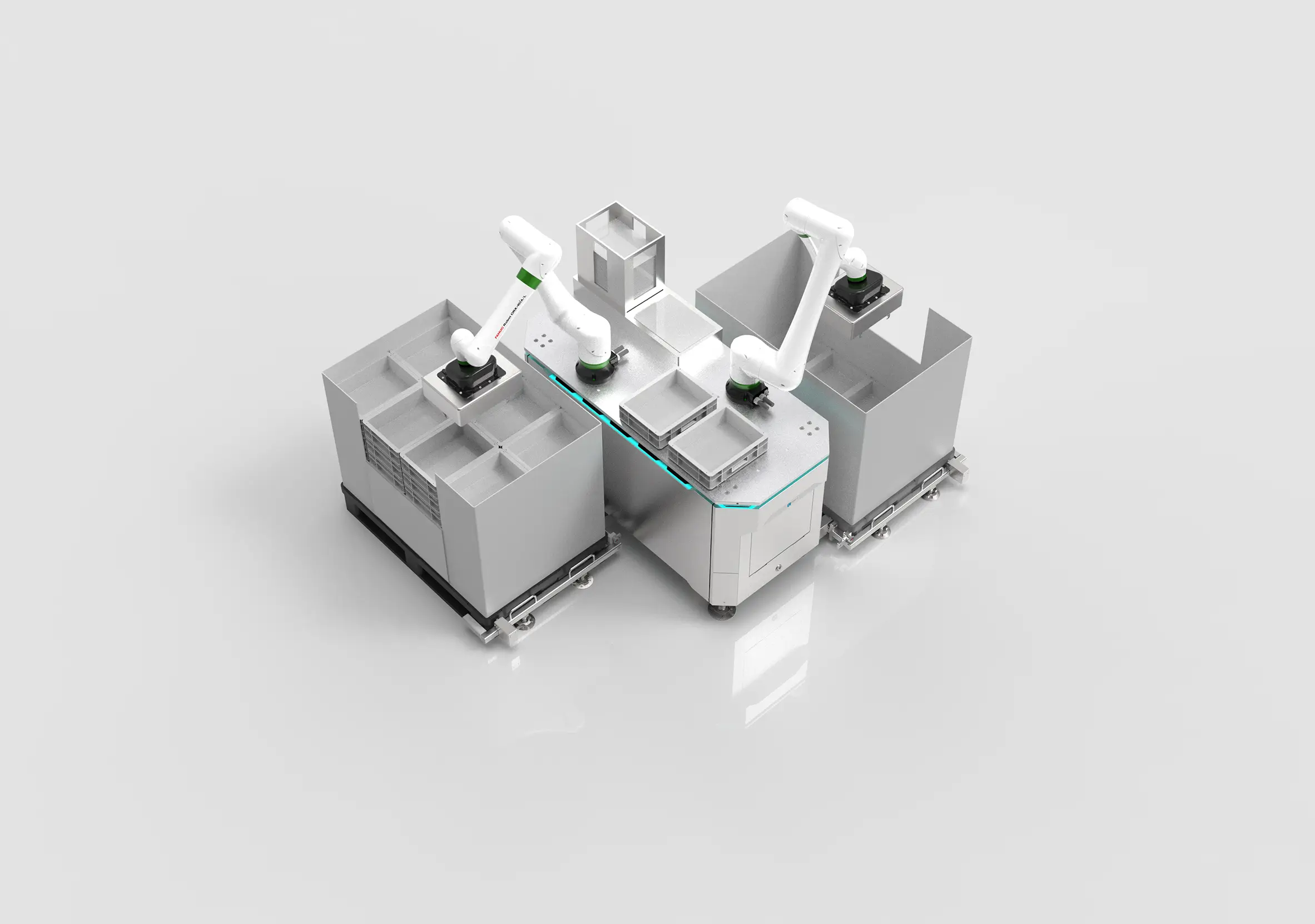

Automated Loading, Unloading & Packing

The RoboVial offers total flexibility. It seamlessly unloads filling lines and fully automates the loading and unloading of inspection machines. Finally, it arranges vials into consistent patterns and packs them securely into multi-use boxes.

Multi-Format Ready

The system is designed to handle a wide range of vial sizes, from 2R to 30R, providing the flexibility you need for diverse production requirements.

Precise Vial Handling

A pre-orientation system and gentle pushers ensure that vials are inserted into the box with a consistent and repeatable pattern every time.

AGV Ready

Designed for the factory of the future, the system allows for seamless integration with Automated Guided Vehicles (AGVs) for fully automated pallet exchange.

High Autonomy

The system buffers vials to keep the process running during pallet exchange, giving the operator approximately 4 minutes of changeover time.

Rapid Deployment

The completely modular design, based on our standard platforms, allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT).

Optional Labeling

An optional labeling system can be integrated directly into the process, allowing for automated box labeling before palletizing.

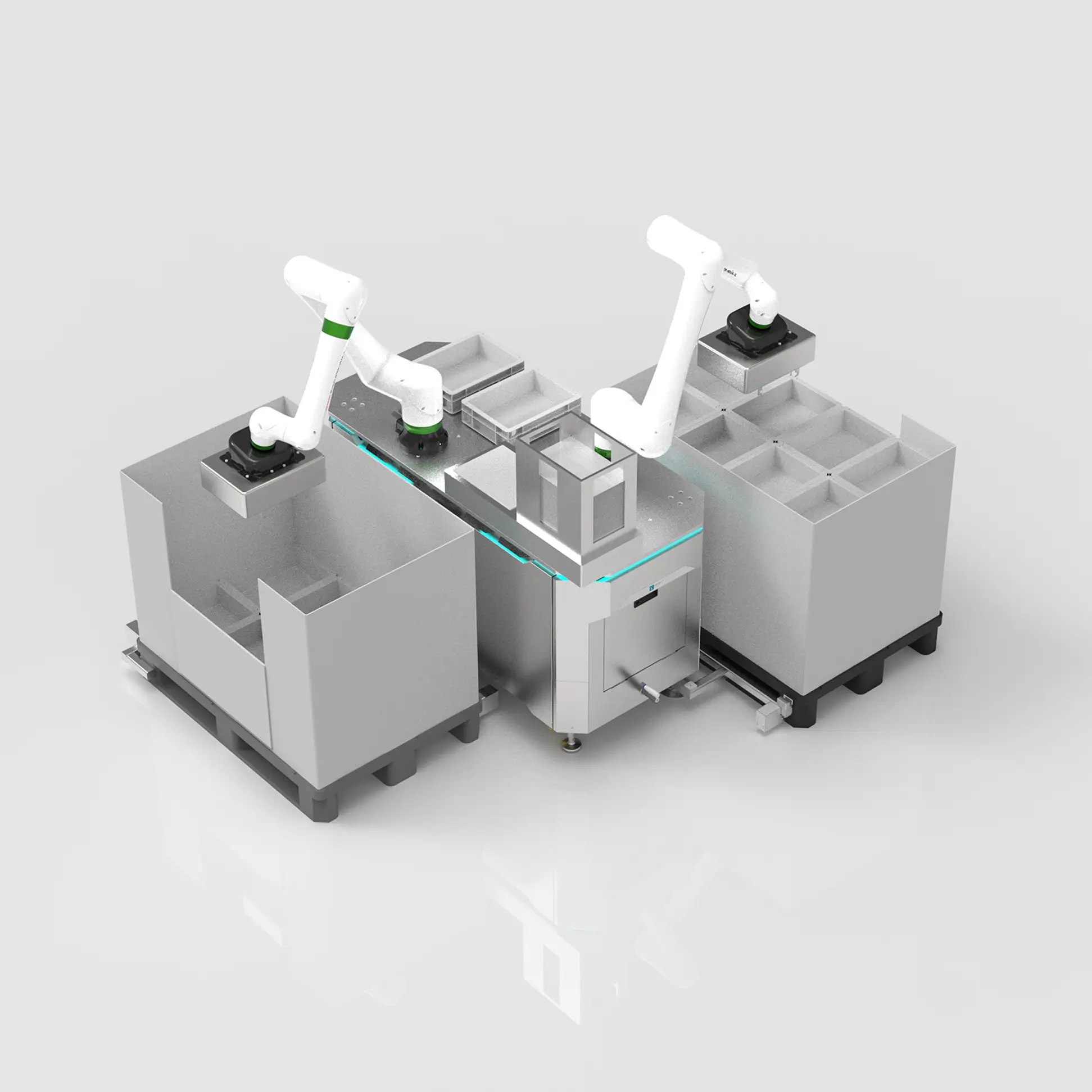

Automated Loading, Unloading & Packing

The RoboVial offers total flexibility. It seamlessly unloads filling lines and fully automates the loading and unloading of inspection machines. Finally, it arranges vials into consistent patterns and packs them securely into multi-use boxes.

Multi-Format Ready

The system is designed to handle a wide range of vial sizes, from 2R to 30R, providing the flexibility you need for diverse production requirements.

Precise Vial Handling

A pre-orientation system and gentle pushers ensure that vials are inserted into the box with a consistent and repeatable pattern every time.

AGV Ready

Designed for the factory of the future, the system allows for seamless integration with Automated Guided Vehicles (AGVs) for fully automated pallet exchange.

High Autonomy

The system buffers vials to keep the process running during pallet exchange, giving the operator approximately 4 minutes of changeover time.

Rapid Deployment

The completely modular design, based on our standard platforms, allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT).

Optional Labeling

An optional labeling system can be integrated directly into the process, allowing for automated box labeling before palletizing.

Automated Loading, Unloading & Packing

The RoboVial offers total flexibility. It seamlessly unloads filling lines and fully automates the loading and unloading of inspection machines. Finally, it arranges vials into consistent patterns and packs them securely into multi-use boxes.

Multi-Format Ready

The system is designed to handle a wide range of vial sizes, from 2R to 30R, providing the flexibility you need for diverse production requirements.

Precise Vial Handling

A pre-orientation system and gentle pushers ensure that vials are inserted into the box with a consistent and repeatable pattern every time.

AGV Ready

Designed for the factory of the future, the system allows for seamless integration with Automated Guided Vehicles (AGVs) for fully automated pallet exchange.

High Autonomy

The system buffers vials to keep the process running during pallet exchange, giving the operator approximately 4 minutes of changeover time.

Rapid Deployment

The completely modular design, based on our standard platforms, allows for fast and efficient Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT).

Optional Labeling

An optional labeling system can be integrated directly into the process, allowing for automated box labeling before palletizing.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.