Packing Medical Products

Packing medical products is vital to protect them from environmental influences during transport and storage. Our Solution helps you to keep your products safe and intact until the moment they come into action.

Packing Medical Products

Packing medical products is vital to protect them from environmental influences during transport and storage. Our Solution helps you to keep your products safe and intact until the moment they come into action.

Packing Medical Products

Packing medical products is vital to protect them from environmental influences during transport and storage. Our Solution helps you to keep your products safe and intact until the moment they come into action.

What’s the Struggle with the Packing of Medical Products?

The packing of medical devices and other products that require special protection for transport and storage is one of the final steps in the manufacturing process. It implies bringing together different products with different kinds of packaging – and here lies the challenge of this step.

Manufacturers need to be extremely flexible: Both the medical product and the type of secondary packaging change regularly.

Uncompromising Quality

Leverage state-of-the-art camera and sensor tech to ensure 100% precision. Eliminate errors before they happen.

Instant Adaptability

We provide you with a flexible packaging solution that can easily be adapted to varying packaging requirements.

Maximize Uptime

Keep your supply chain moving and drastically reduce downtime with a system that runs reliably on its own.

Audit-Ready Compliance

Our Cleanroom and GMP-compliant design takes the headache out of regulatory requirements.

Empower Your Workforce

Free up your skilled staff to focus on high-value work where their expertise is truly needed.

Cut Costs, Not Corners

Reduce manual errors, minimize secondary packaging damage, and lower operational costs.

What’s the Struggle with the Packing of Medical Products?

The packing of medical devices and other products that require special protection for transport and storage is one of the final steps in the manufacturing process. It implies bringing together different products with different kinds of packaging – and here lies the challenge of this step.

Manufacturers need to be extremely flexible: Both the medical product and the type of secondary packaging change regularly.

Uncompromising Quality

Leverage state-of-the-art camera and sensor tech to ensure 100% precision. Eliminate errors before they happen.

Instant Adaptability

We provide you with a flexible packaging solution that can easily be adapted to varying packaging requirements.

Maximize Uptime

Keep your supply chain moving and drastically reduce downtime with a system that runs reliably on its own.

Audit-Ready Compliance

Our Cleanroom and GMP-compliant design takes the headache out of regulatory requirements.

Empower Your Workforce

Free up your skilled staff to focus on high-value work where their expertise is truly needed.

Cut Costs, Not Corners

Reduce manual errors, minimize secondary packaging damage, and lower operational costs.

What’s the Struggle with the Packing of Medical Products?

The packing of medical devices and other products that require special protection for transport and storage is one of the final steps in the manufacturing process. It implies bringing together different products with different kinds of packaging – and here lies the challenge of this step.

Manufacturers need to be extremely flexible: Both the medical product and the type of secondary packaging change regularly.

Uncompromising Quality

Leverage state-of-the-art camera and sensor tech to ensure 100% precision. Eliminate errors before they happen.

Instant Adaptability

We provide you with a flexible packaging solution that can easily be adapted to varying packaging requirements.

Maximize Uptime

Keep your supply chain moving and drastically reduce downtime with a system that runs reliably on its own.

Audit-Ready Compliance

Our Cleanroom and GMP-compliant design takes the headache out of regulatory requirements.

Empower Your Workforce

Free up your skilled staff to focus on high-value work where their expertise is truly needed.

Cut Costs, Not Corners

Reduce manual errors, minimize secondary packaging damage, and lower operational costs.

Flexible Packing and Sealing

Our Medical Packaging Solution helps you to automate medical product packaging, despite the great variability of this process. Nevertheless, flexibility is one of the platform’s major strengths, being easily adaptable to changes in secondary packaging or the products to be covered.

Software-Driven

Control complex robotic processes easily via tablet. Teach in new packaging formats without any programming skills.

Full Traceability

Free up your skilled workers. Create transparency for audits and traceability down to the individual patient.

Sterile & Safe

Surgical instruments or other - our solution maintains the integrity of your products until they reach the patient.

Flexible Packing and Sealing

Our Medical Packaging Solution helps you to automate medical product packaging, despite the great variability of this process. Nevertheless, flexibility is one of the platform’s major strengths, being easily adaptable to changes in secondary packaging or the products to be covered.

Software-Driven

Control complex robotic processes easily via tablet. Teach in new packaging formats without any programming skills.

Full Traceability

Free up your skilled workers. Create transparency for audits and traceability down to the individual patient.

Sterile & Safe

Surgical instruments or other - our solution maintains the integrity of your products until they reach the patient.

Flexible Packing and Sealing

Our Medical Packaging Solution helps you to automate medical product packaging, despite the great variability of this process. Nevertheless, flexibility is one of the platform’s major strengths, being easily adaptable to changes in secondary packaging or the products to be covered.

Software-Driven

Control complex robotic processes easily via tablet. Teach in new packaging formats without any programming skills.

Full Traceability

Free up your skilled workers. Create transparency for audits and traceability down to the individual patient.

Sterile & Safe

Surgical instruments or other - our solution maintains the integrity of your products until they reach the patient.

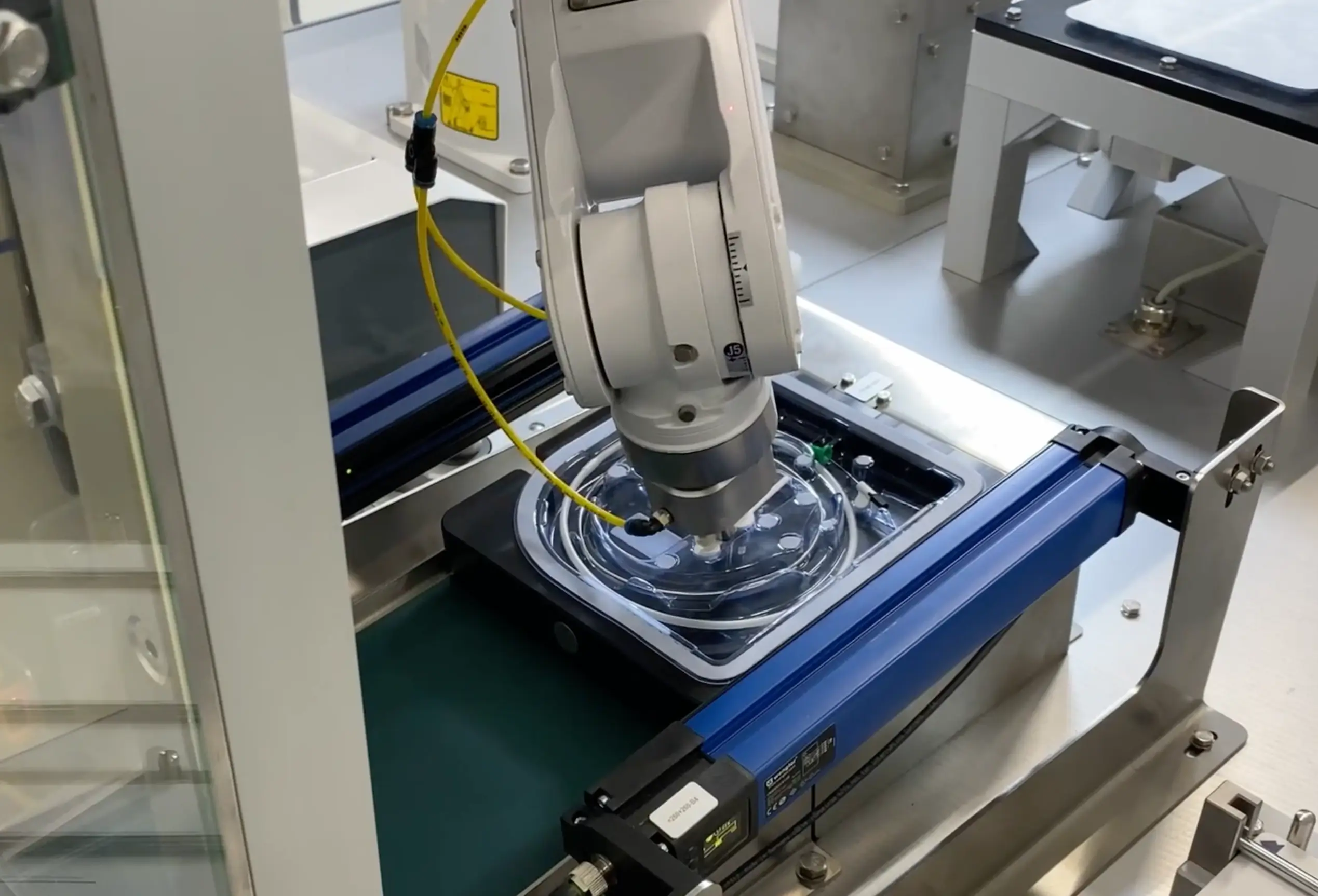

Showcase of the Packing Solution

Automated Picking and Packing for highest demands

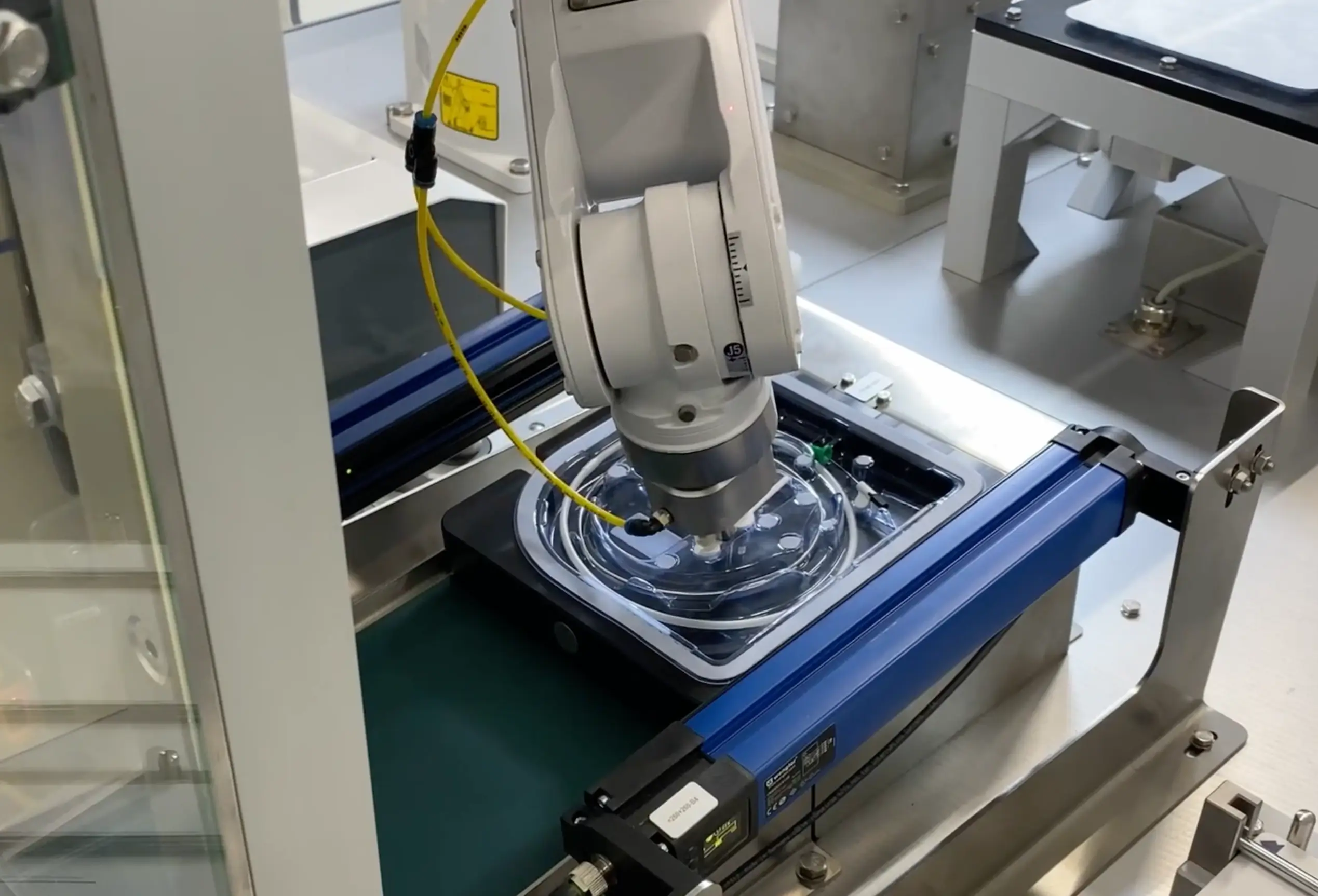

Showcase of the Packing Solution

Automated Picking and Packing for highest demands

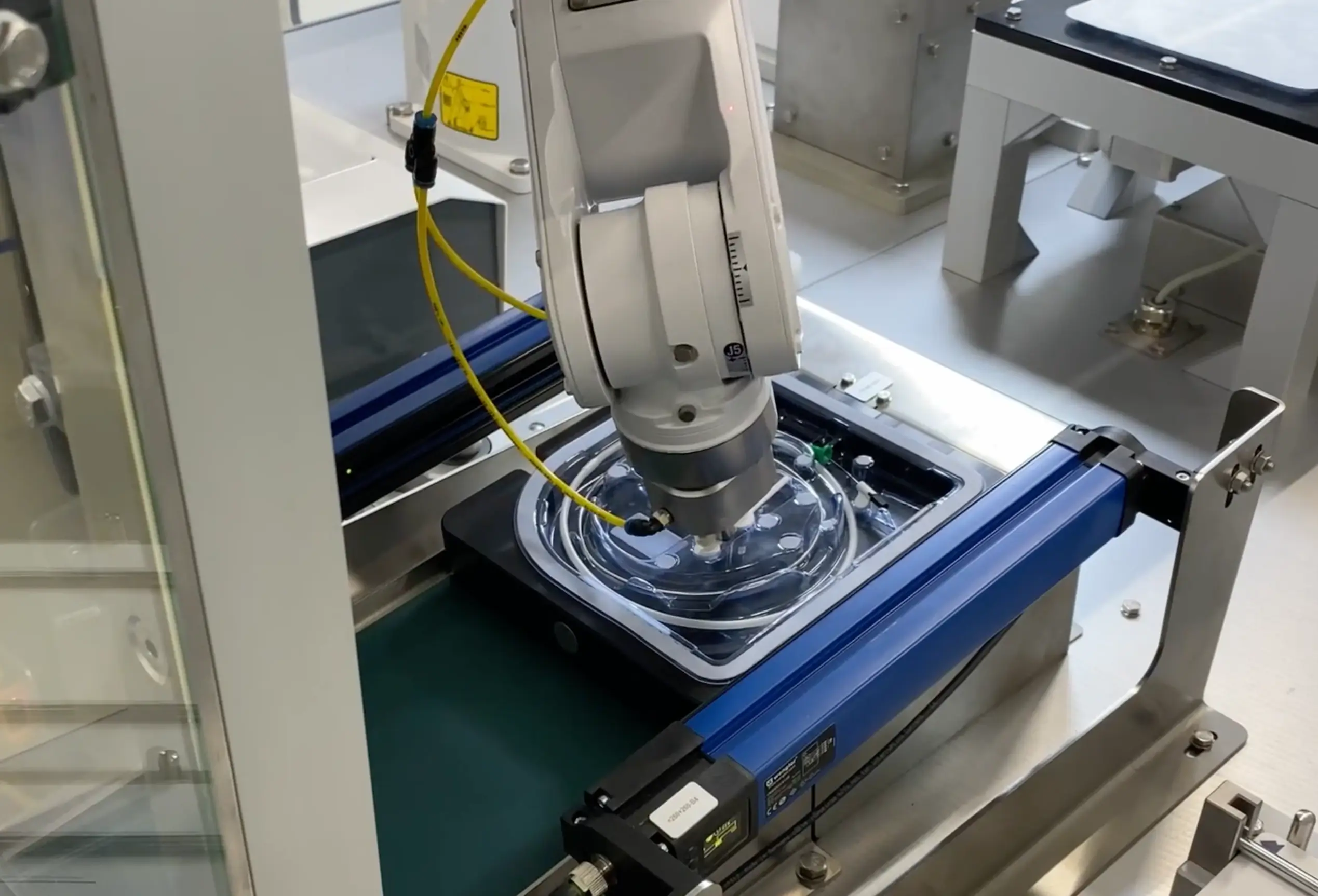

Showcase of the Packing Solution

Automated Picking and Packing for highest demands

Where automated packaging solutions play out their strengths

In High Mix / Low Volume (HMLV) manufacturing, these systems are instrumental in efficiently packaging products like personalized therapies, specialized pharmaceuticals, intricate medical instruments, diagnostic kits, and sterile surgical supplies.

These diverse medical items demand versatile packaging solutions that can adapt to their unique requirements while maintaining the utmost precision and quality, making automation an invaluable asset in the healthcare industry.

Where automated packaging solutions play out their strengths

In High Mix / Low Volume (HMLV) manufacturing, these systems are instrumental in efficiently packaging products like personalized therapies, specialized pharmaceuticals, intricate medical instruments, diagnostic kits, and sterile surgical supplies.

These diverse medical items demand versatile packaging solutions that can adapt to their unique requirements while maintaining the utmost precision and quality, making automation an invaluable asset in the healthcare industry.

Where automated packaging solutions play out their strengths

In High Mix / Low Volume (HMLV) manufacturing, these systems are instrumental in efficiently packaging products like personalized therapies, specialized pharmaceuticals, intricate medical instruments, diagnostic kits, and sterile surgical supplies.

These diverse medical items demand versatile packaging solutions that can adapt to their unique requirements while maintaining the utmost precision and quality, making automation an invaluable asset in the healthcare industry.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

Let’s Talk

Automation is a long-term commitment. We partner with manufacturers who think in lifecycles. If you are evaluating automation for a new product, scaling a process, or preparing for a future pipeline - let’s talk.

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

See what's new

5 Reasons for automated medical device assembly

The assembly of medical devices is often much more complex than the manufacturing of traditional consumer goods. The reasons are ...

The Last Manual Bottleneck in Pharma Manufacturing

The economic impact of manual tub and vial handling extends far beyond visible labor costs. While managers can calculate hourly wages, ...

5 Reasons Why Flexibility is the Future of Manufacturing

The pharmaceutical industry is experiencing a fundamental transformation. As personalized medicine reshapes treatment paradigms ...

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.

Contact our team

From initial questions to your custom MicroFactory solutions – our team is here to assist you.